Laboratories of strength research and metallography

Laboratories of strength research and metallography are dealing with testing of metals, plastics and other technical materials by destructive and non-destructive methods. These allow to determine the mechanical properties in tension (compression), bend, impact bend, fracture testing and hardness measurements by indentation tests performed on base metals as well as the material characteristics of welded, brazed/soldered and bonded joints in agreement with the valid standards and regulations.

The workplace is furnished with appropriate test equipment with regular approval of measurement accuracy and is also qualified for performing expert quality assessment of technological procedures as authorised person SKTC-176 in welding, casting, forming, machining and heat treatment by application of destructive and non-destructive methods.

- tensile, compression and bend tests

- impact bend tests

- fracture tests

- deep-drawing ability test of sheets (Erichsen)

-

hardness measurements (methods by Brinell, Vickers and Rockwell)

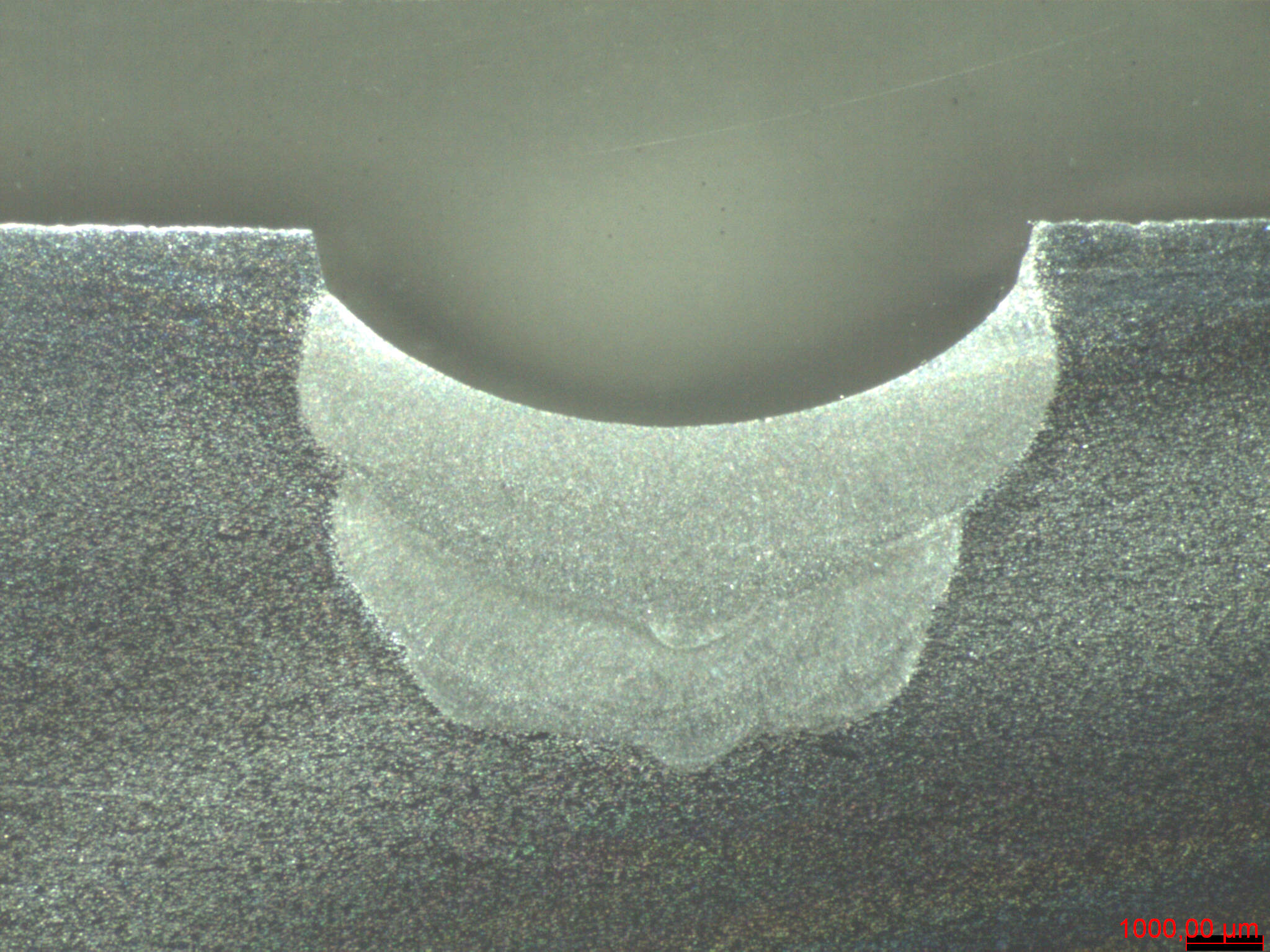

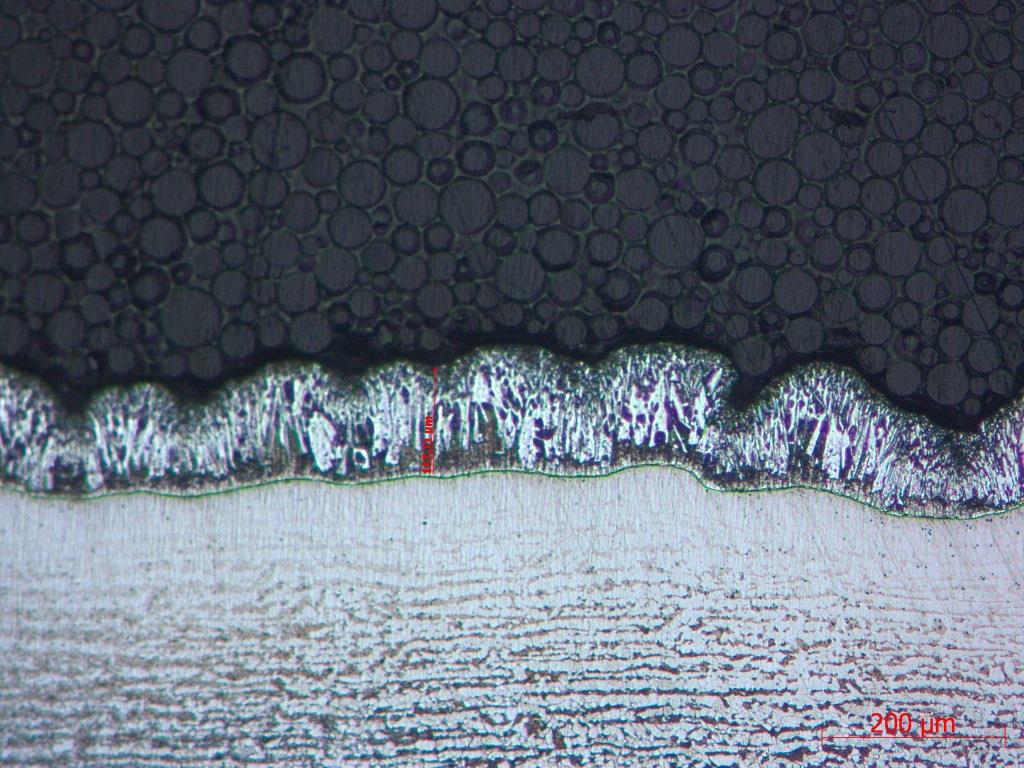

- macroscopic and microscopic analysis

- grain size estimation

- coating thickness measurement

- visual

-

capillary (dye penetrant)

- magnetic

- ultrasonic

- thickness measurement by ultrasound

- approving welding procedures – WPQR

- quality assessment of welded joint after its fabrication

-

quality analysis of input materials and products

- diagnostics of welded structures